Knowing the difference between flexographic and lithographic lamination helps you choose the right one. Find the best technique to apply to your boxes here!

If you wish to sell your products more, your packaging boxes should appeal to customers. This is where the lamination process is important. Speaking of this printing stage of your boxes, there are two popular options favored by many brands from different industries. Let’s explore the difference between flexographic and lithographic lamination! Flexographic and lithographic; what are they, and which one should you choose?

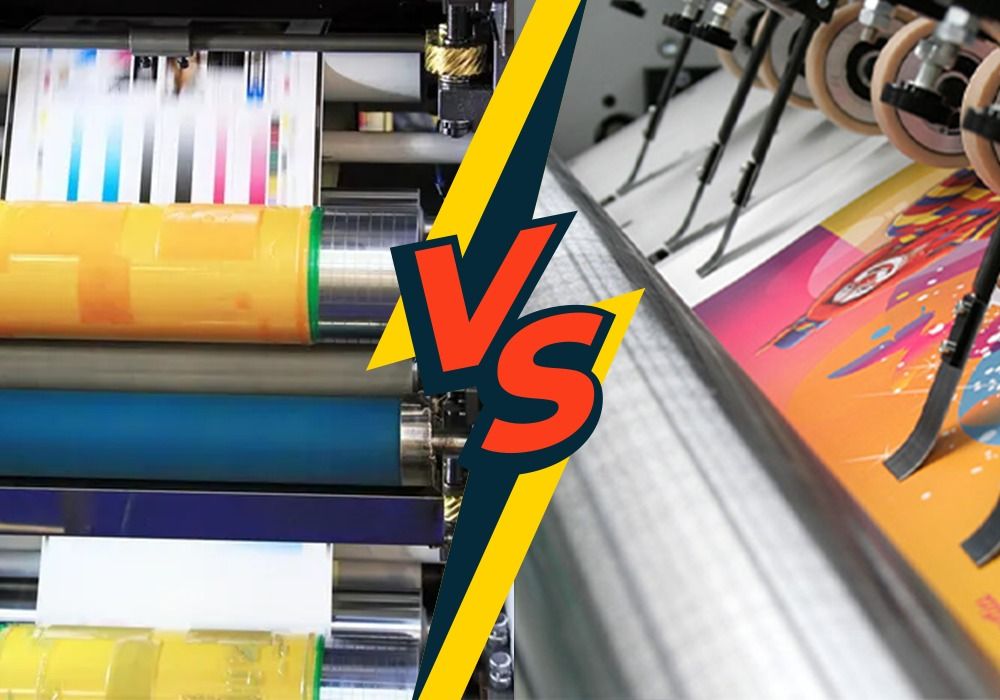

Flexographic vs Lithographic Lamination

When it comes to highlighting and selling your exclusive product in the box, you will need to think outside the box. Your cardboard boxes don’t suppose to be looking standard and boring. In fact, customization can be the best branding technique you can use. Imagine having countless boxes with your branding in circulation all over the world. Yes, your business can eventually grab tremendous benefits from these boxes.

You must read about the advantages of custom cardboard boxes in business here!

Whether for cosmetic boxes or cigarette boxes, the printing process you choose for your boxes must be convenient and inexpensive. Speaking of custom printing, flexographic vs. lithographic ends up being an age-old debate in the packaging industry. Even today, these two techniques are the standard and famous processes in the packaging and printing industry.

Yet, you will need these two altogether when it comes to printing modern custom packaging boxes. After all, printing is a tedious task and requires some optimization. Various factors such as available budget, time constraints, print quality, and packaging usage (delivery or retail) play a role here.

Each of the printing processes comes with its advantages. Additionally, each can give your product packaging a different look at a different cost. In this context, knowing what each printing process has to offer will help you better plan your packaging design and budget.

So if you are ordering custom boxes, you need to clear up the confusion between flexographic and lithographic lamination. Let’s dive in.

Flexographic Lamination

Flexographic lamination is a high-volume printing technique using flexible letterpress. The packaging supplier applies the ink first to the plate and then to the surface. This method is famous as an inexpensive printing process. It has come a long way since the introduction of direct laser engraving in the 1970s.

Learn More Ways Fluorescent Colors Make Your Packaging Look More Dazzling

The Advantages of Using Flexographic

Flexographic lamination is an economical option. It allows the manufacturer to print and cut the boxes at once. Below are some advantages you will get from using this lamination technique!

- This technique is suitable for printing large numbers of boxes that do not require any color detail

- It comes with the versatility that makes it easy to use on non-absorbent materials

- Flexographic lamination is compatible to use with both water-based and oil-based inks

Lithographic Lamination

Lithographic lamination is a printing process originally based on the immiscible substances oil and water. German author Alois Senefelder invented this method in 1796. The goal was to find an inexpensive way to publish his theatrical productions. Today, many brands use lithographic lamination for anything that requires vivid colors. You can eventually print your boxes in large quantities easily with this technique.

The advantages of using lithographic lamination:

- It allows for high color detail

- It offers excellent image quality at a low price

- This technique comes with the flexibility to let you print on any type of surface

Which One to Choose?

The type of printing process you ultimately choose should only depend on your design. Flexographic printing will be ideal if you wish to be minimal with single bright colors. On the other hand, if your design contains photographs or intricate details requiring full-color printing, you should consider applying lithographic printing.

Both flexographic and lithographic lamination are undoubtedly interesting topics to discuss. Yet, of course, both come with their strengths and weaknesses. Thus, you can decide the one to choose when you have clarity on parameters such as:

- The quantity of custom boxes you need to print

- Your spending budget

- The quality requirements

- The available time

The Similarities and Differences Between Flexographic and Lithographic Lamination

Both flexograpic and lithographic lamination are traditional high-volume printing processes that use printing plates. In addition, both processes are inexpensive for simple high-volume printing. Of course, there are some important differences between these two innovative lamination techniques you should consider.

Lithographic lamination allows for decorations such as foil stamping and embossing, which increases production costs. What’s more, flexographic printing is less complicated. For this technique, you can use a properly stored image carrier many times until you need to replace it.

Meanwhile, you will find the flexographic lamination as a highly versatile option. In other words, you can easily print both porous and non-porous surfaces with this technique. Hence, making this printing technique ideal for various substrates. Eventually, both lithographic and flexographic laminations can use permanent inks. However, lithographic lamination offers more color detail and versatility.

Which printing process is better between the two to use on custom boxes?

In general, lithographic printing is suitable for full-color printing with detailed patterns. Another great thing is that it offers more finishing options. Flexographic printing, on the other hand, we can say that it is a more direct process to help you reduce printing time and costs. However, this process does not provide the detailed color and image quality of lithographic lamination. So, the choice of the best one depends on the specific needs of your project.

Wrapping Up

Choosing the right printing style for your custom boxes is one of the most effective methods to highlight your products. Even better, printing your brand name on the boxes will surely help you promote your business wider. So, speaking of the difference between flexographic and lithographic lamination, we know that there are many things to consider. In this context, make sure to choose the one that meets your packaging needs and business requirements at the same time! Again, it is yours to decide the best one to choose.

Good luck with your printing!

If you wish to sell your products more, your packaging boxes should appeal to customers —- million dollar point.